With POLYTEC SOLUTION FORCE, we are pooling our expertise in materials, technology and product development. Our goal: solutions that really fit. We get involved early: from the first sketch to the start of series production, we accompany the process step by step - with a clear focus on what our customers need and what the environment demands.

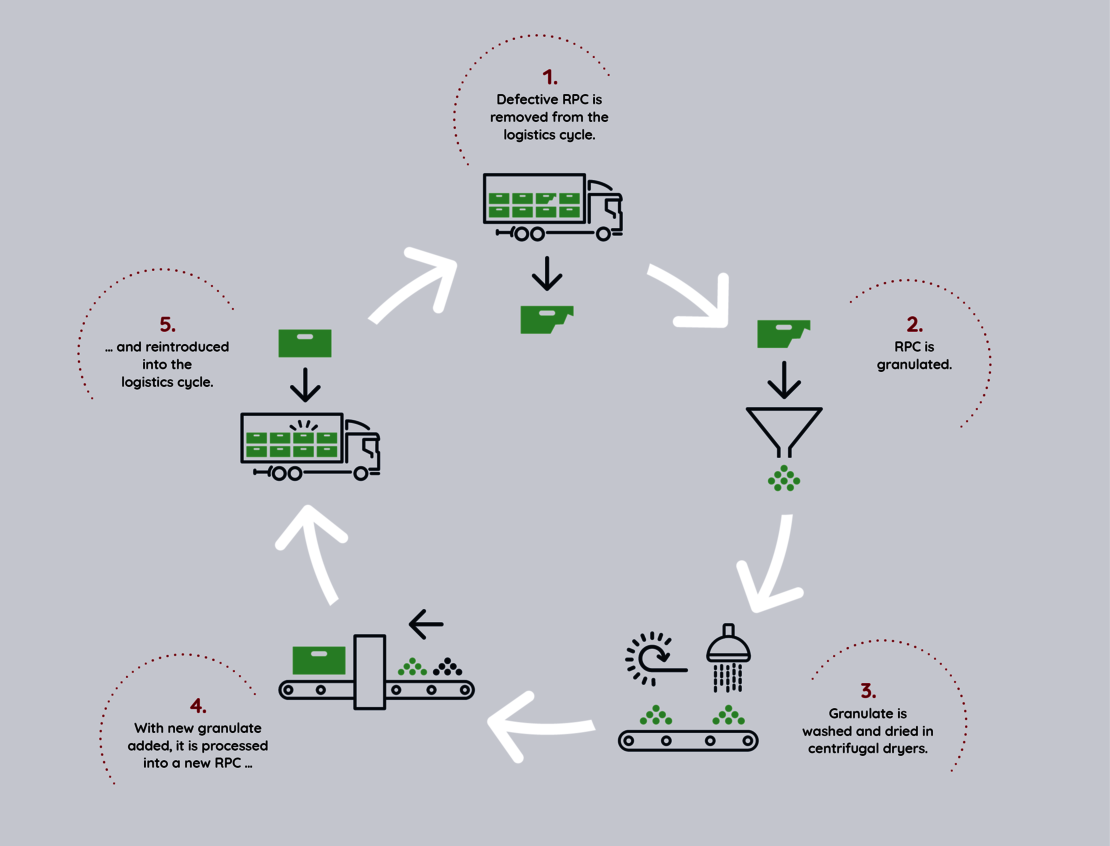

We think outside the box and beyond pure production - towards an intelligent cycle in which energy, materials and processes are perfectly harmonised. It doesn't matter which technology is used for production later on. We translate ideas into plastic solutions that work and are well thought out right through to recycling.

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/e/e/csm_Header_670e97173d.jpeg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/f/3/csm_Nachhaltigkeit_Menue_629d33ed20.jpg)