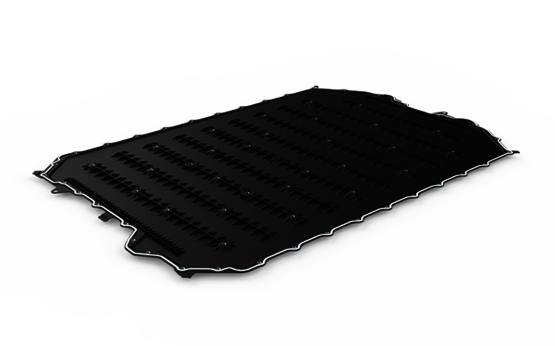

Compared to the predecessor model made of aluminium, the new thermoplastic underbody solution, which primarily protects the battery from mechanical impacts near the ground, also scores in terms of sustainability. This is because the construction, which is around a quarter lighter, contributes to a significant reduction in the CO2 footprint.

On the one hand, the weight reduction leads to an increase in the efficiency of the electric SUV. On the other hand, the chosen composite material with high elasticity and excellent energy absorption ensures increased adaptability to all forces to which a vehicle may be exposed. The underride protection is thus jointly responsible for the longevity of the vehicle and contributes to sustainable electrification and emission reduction in mobility.

Another important premise during the development phase was recyclability, which is ensured by the use of thermoplastic material. Thus, the component can be returned to the material cycle at the end of its useful life and the consumption of fossil resources can be reduced. Last but not least, the highly efficient one-shot production process with only one mould leads to a significant reduction in climate-relevant emissions.

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/e/e/csm_Header_670e97173d.jpeg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/f/3/csm_Nachhaltigkeit_Menue_629d33ed20.jpg)

![[Translate to Englisch:]](/fileadmin/CORPORATE_WEBSITE/05_UEBER_POLYTEC/Blog/JEC-Innovation-Award-fuer-AUDI-und-POLYTEC.png)